Why Label Quality Is Now a Brand Risk – Not Just a Production Detail

For many businesses, labels are still treated as a small component of the overall pack. They’re ordered late in the process, compared on price and expected to arrive on time and look good.

But today, label quality directly affects brand reputation, compliance and production efficiency.

When a label fails, it rarely stays a production issue. It can stop application lines, delay product launches, create compliance risks and damage consumer trust.

That’s why at Baker Labels, quality is built into every stage of the process – not inspected at the end.

Where Label Failures Really Start

The Importance of Technical Planning

Most label failures do not start on press. They begin much earlier – at the technical planning stage.

“A lot of failures can be prevented before production even begins,” says Jamie Godson, Technical Manager at Baker Labels. “Before we go to press, we need to understand the end use of the label. Once we know that, we can build the right construction – materials, adhesive, print process and finish – so the label simply does its job. No problems. It just works.”

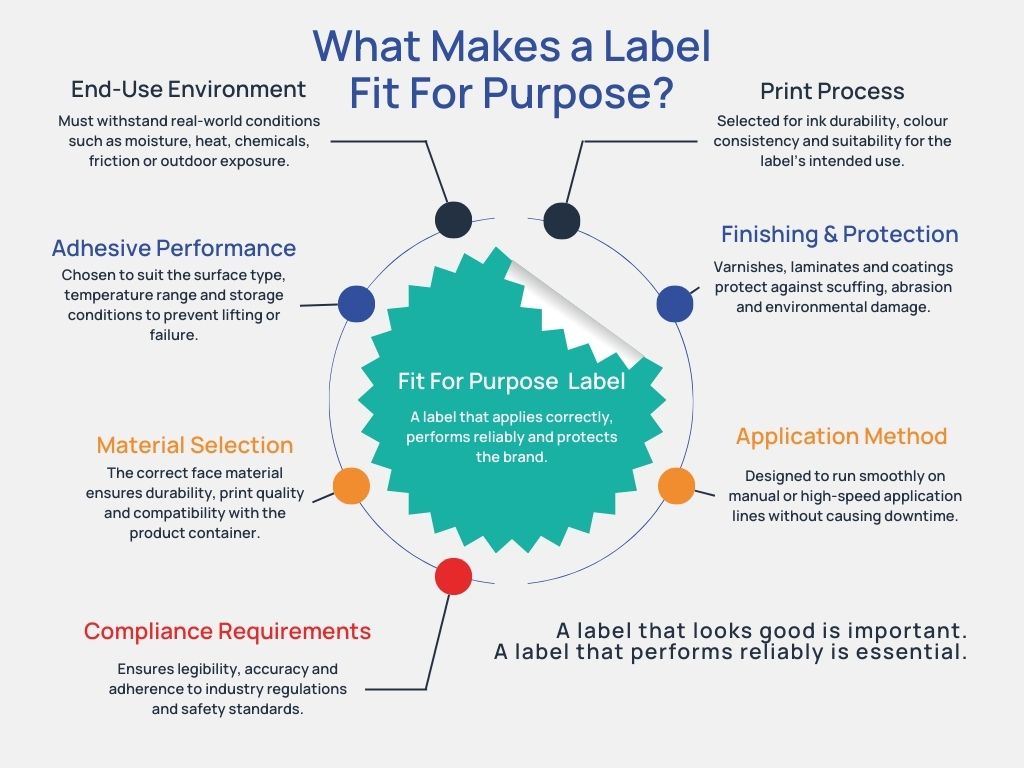

Understanding how and where a label will be used is critical to preventing label failure.

Understanding End Use and Environment

A wine label going into an ice bucket requires different adhesive performance to a label applied to an engine component exposed to oil and heat. A product stored outdoors needs inks with strong light fastness. A label for high-speed application must release cleanly from the liner.

“Materials and adhesives massively affect real-world performance,” Jamie explains. “It’s not just about how it looks. It has to be fit for purpose.”

If you’re selecting substrates for your own production, our self-adhesive label materials division supplies a wide range of high-performance materials to the print trade.

Getting material selection right at the start removes risk later.

How Small Label Issues Become Big Problems

Die Cutting and Application Line Risk

In label production, small technical details can have significant operational consequences.

“It might look like a small issue – slightly heavy die cutting,” says Jamie. “But that can cause the liner to break on the applicator. What seems minor in production becomes a big problem for the next person down the line.”

When application lines are running at speed, even a minor inconsistency can result in costly downtime.

Text Legibility and Compliance

Text clarity is not just an aesthetic consideration. In regulated sectors, it becomes a compliance requirement.

“If text is filling in or too small, that’s not just cosmetic,” Jamie explains. “It can become a compliance issue.”

Accurate, legible information protects both the consumer and the brand.

Brand Colour Consistency on Shelf

Brand colour is another area where minor print variation becomes magnified.

“For a printer, something might look slightly off. But for a brand sitting on a retail shelf, that inconsistency is amplified.”

Maintaining consistent print quality and colour control is a core part of our quality control processes.

Production Downtime and Reprints

From a commercial perspective, label failure extends well beyond the cost of replacing the labels.

“The assumption is often that the only cost is reprinting,” says Commercial Manager Jamie Doogan. “In reality, that’s only a part of it.”

If labels don’t run smoothly on application lines, production slows or stops. If deliveries need to be replaced urgently, logistics costs increase.

“The label might be one of the lowest-cost components in the pack,” Jamie explains, “but when it goes wrong, it can quickly become one of the most expensive.”

Speed to Market and Supply Chain Pressure

Labels are often one of the last components ordered in a packaging project. Turnaround times are tight.

“That’s exactly why quality matters,” Jamie says. “You want that delivery to happen once – not twice.”

In fast-moving supply chains, reprints are not just inconvenient. They are commercially disruptive.

Brand Reputation and Consumer Trust

If a label lifts, scuffs or contains incorrect information, the consumer does not see the printer – they see the brand.

Retailers expect consistency. Consumers expect clarity.

When label performance falls short, brand credibility absorbs the impact.

Commodity Purchasing vs Fit-for-Purpose Labels

Because labels are relatively easy to reorder, they are sometimes treated as a commodity.

But two labels that look identical in a box can perform very differently in real-world conditions.

“We can’t just robotically print what we’re given,” says Jamie Godson. “We have to use our experience and advise on what will actually work.”

That may involve adjusting specification, recommending alternative adhesives or advising on finishing techniques such as label embellishments and finishing techniques.

Early involvement reduces risk.

“It’s always better to iron out these production challenges at the design stage rather than to reprint thousands of labels,” Jamie Doogan adds. “The cost curve of the whole process becomes steeper the further you get into production.”

Why Experience Still Matters in Quality Control

Human Judgement in Label Printing

Despite automation and inspection systems, experience remains critical.

After 45 years in the label industry, Quality Controller, Noel Finn describes quality simply:

“Quality control is having the perfect reel of labels ready to go out to the customer. We check everything – colours, cutting, varnishes – and make sure it matches exactly what’s been asked for.”

“You just see things,” Noel adds. “That comes from experience.”

Catching Problems Before Despatch

Technology supports the process, but it does not replace judgement.

“If we let something go, the whole job’s no good. You’d have to start again. The key is to stop anything wrong leaving the building.”

That preventative approach is central to quality control in label printing.

From Label Supplier to Label Partner

Advisory Approach to Label Specification

A good label partner looks beyond the print file.

“They consider how the label will be applied, what environment it’s going into and whether the specification truly supports that,” says Jamie Doogan.

That advisory role becomes increasingly important in high-volume production and regulated sectors.

The same performance-led thinking applies across our flexible packaging solutions, where material functionality is equally critical.

Why We Don’t Avoid the Difficult Jobs

Not every label project is straightforward.

Multi-layer constructions, unusual materials, tight tolerances, demanding environments — these are often the jobs that expose weaknesses in process and communication.

At Bakers, we don’t shy away from those conversations.

“We have a very consistent team here,” says Tom Baker. “More often than not, it’s the same person running your work. There’s nothing like the knowledge of genuinely having done it before.”

That continuity matters. It means experience is retained, lessons are shared and improvements are embedded – not lost.

And when challenges arise, they are addressed head-on.

“If there’s a quality issue,” Tom adds, “it’s important that someone is technically capable of getting to the root of the problem and doing something about it.”

In some cases, businesses move work not because of a single mistake — but because issues are not resolved properly.

Our approach is different.

We investigate.

We take accountability.

We implement corrective actions.

And we update processes so it doesn’t happen again.

That mindset turns challenges into improvements.

Label Quality as Brand Protection

In today’s market, label quality is not just a production detail. It is part of brand protection, operational resilience and regulatory confidence.

Treating labels as a strategic component – rather than a commodity – reduces risk and supports long-term brand performance.

As an independent UK label manufacturer established in 1973, Bakers builds quality into every stage of the process.

Because sometimes quality is proven not when nothing goes wrong, but in how a team responds when something does. Once a label leaves our factory in Brentwood, it represents more than print and adhesive.

It represents the brand.

Frequently Asked Questions About Label Quality

What causes label failure?

Label failure usually starts at the planning stage. Incorrect material selection, unsuitable adhesive performance, heavy die cutting, poor colour consistency or text legibility issues can all contribute. Understanding end use and environment is key.

Why is label quality important for brand protection?

If a label lifts, scuffs or contains incorrect information, it reflects directly on the brand. High-quality, fit-for-purpose labels protect consumer trust and retailer confidence.

How can businesses reduce the risk of label failure?

Early technical involvement helps ensure the correct material, adhesive and print process are selected. Working with an experienced UK label manufacturer reduces operational and compliance risk.

What makes a label fit for purpose?

A fit-for-purpose label applicates correctly, adheres to the chosen surface, withstands storage conditions and maintains legibility throughout the product lifecycle.

Not sure if your labels are truly fit for purpose?

Sometimes small adjustments make a significant difference.

If you’d value an experienced set of eyes on your next project, we’d be glad to help.